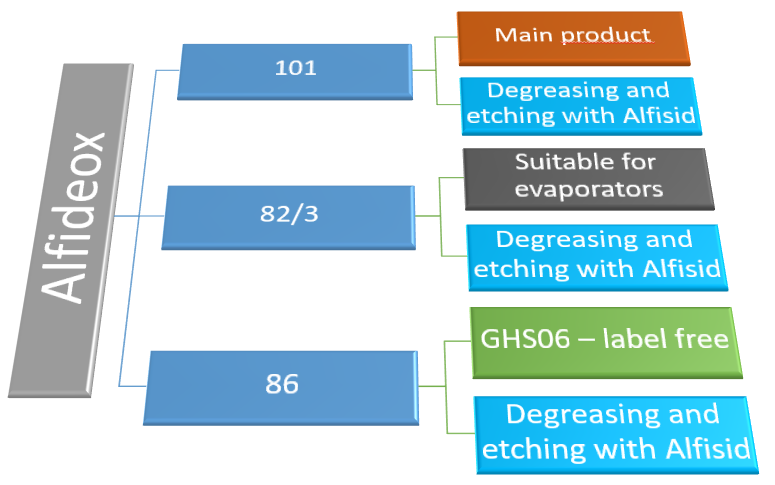

Alfideox 82/3 – 101 – 86

Acid etching systems for more "grip" when powder coating

Perfect in surface activation

In addition to a good cleaning of the surface, a good etching of the material is particularly important when powder coating aluminium. In addition to removing oxide residues and other surface residues that are not removed during cleaning, acid etching with Alfideox enables the surface to be roughened. This in turn gives the subsequent powder coating the necessary "grip". But it is not only the roughening of the surface that is important, but in particular the active and trouble-free surface that this creates. This promotes the formation of a good protective layer in the subsequent corrosion protection process.

Various Alfideox products with different properties are available for this application.

Advantages:

Optimised acid/fluoride ratios ensure perfect etching behavior even in older baths

Separate fluoride additions become superfluous

Effective etching effect even at low application concentration

Alfideox 82/3: ammonium-free and suitable for evaporation systems for rinse water treatment

Automatic dosable liquid products

Degreasing and etching in only one process step through combination with Alfisid products

Multi-stage Alfideox - application possible for flexible etching rates

Alfideox - products without GHS06 labelling are also available in case of stock restrictions

Properties of Alfideox products

Example of a flexible, multi-stage process with an etching rate of 2.2 g/m² applied by spraying. As the products are compatible with each other, no rinsing is required between the etching zones. In the first process step, the focus is on degreasing the surface with a simultaneous low etching rate; in the second, the etching rate can be flexibly adjusted to meet specific specifications (e.g. Qualicoat Seaside Class).