Chromium-free in vertical plants

ENVIROX processes - in use since 2005

Chromium-free pretreatment in vertical installations – long experience

When the first vertical plant with a chromium-free ENVIROX process from Alufinish went into operation in 2005, it was at once something special. The new “waterfall” technology was utilised then for the first time in a facility in Greece in addition to the already well-known spray system. In the new process, the surface is not sprayed with the pretreatment chemicals - instead, they flow over the material surface from top to bottom like a waterfall, performing the cleaning and pickling as well as the required corrosion protection. Numerous vertical plants were put into operation in the following years which implement spray technology, combined spray and waterfall technology – or the waterfall method alone. Meanwhile, the combination of chromium-free ENVIROX pretreatment processes and vertical application engineering for profiles has become well established on the international market. For this purpose, especially chromium-free ENVIROX NR and ENVIROX S processes provide the ideal corrosion protection for aluminium surfaces.

Advantages:

Excellent, chromium-free corrosion protection for aluminium surfaces prior to powder coating

Continuous operations are achievable for aluminium profiles together with a high throughput

Can be used variably in spray, waterfall or combined processes

Choice of “No-Rinse” (ENVIROX NR) or “Rinse” (ENVIROX S) systems

Tried and tested over many years and approved as a corrosion protection process by the quality communities

Automated system control possible

Corrosion protection which is colourless, but still easy to verify

Even though the coatings produced are colourless, they can be easily verified, both qualitatively and quantitively. *VE = fully demineralised water

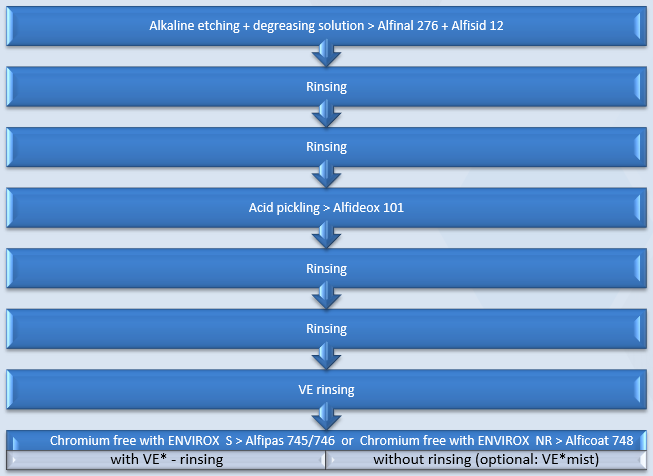

Example of vertical spray plant with alkaline + acidic pretreatment