Produkte

All products at a glance:

With our portfolio of products, we cover all requirements in the areas of anodising and coating at the highest level. We also offer numerous solutions for the iron and zinc pretreatment.

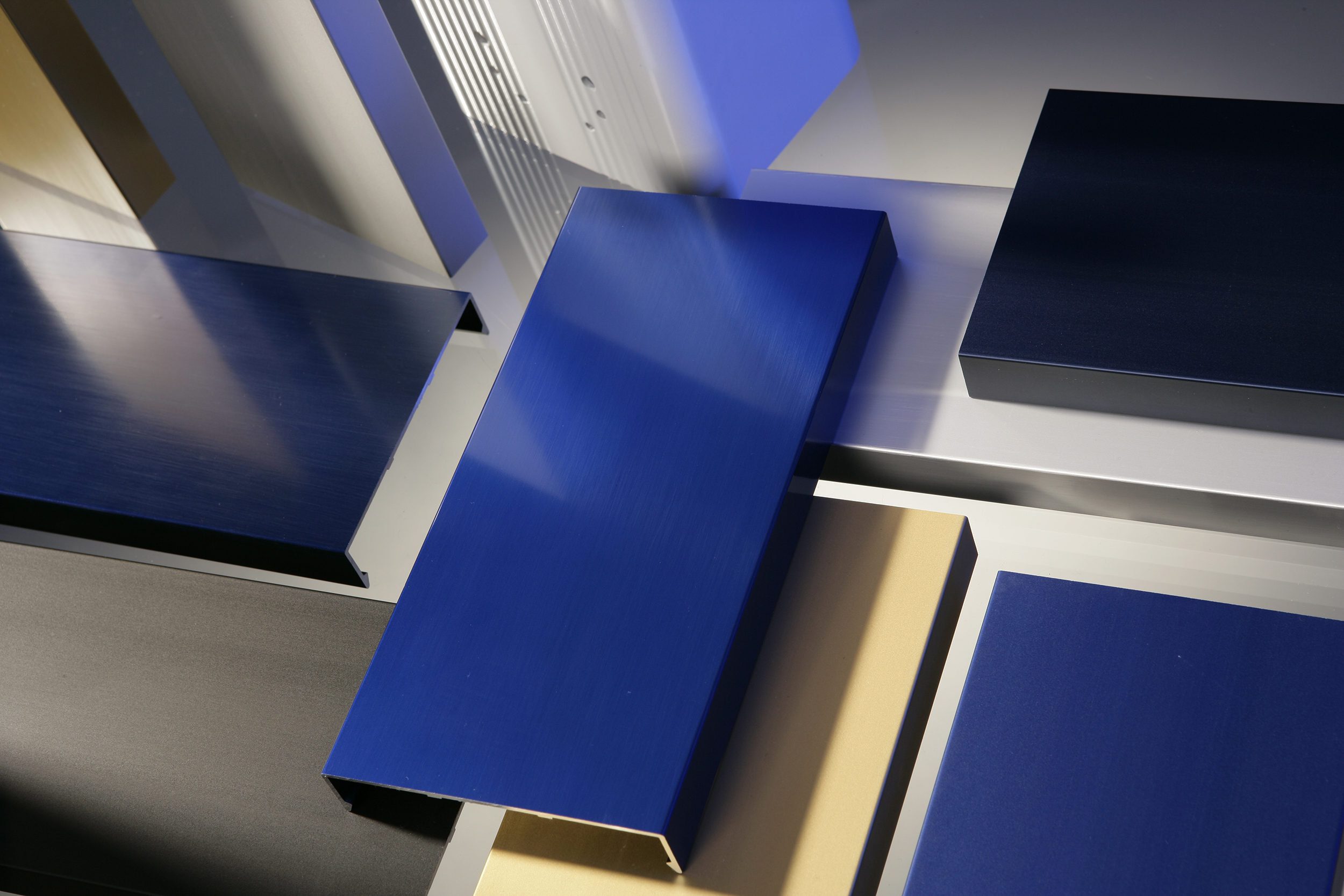

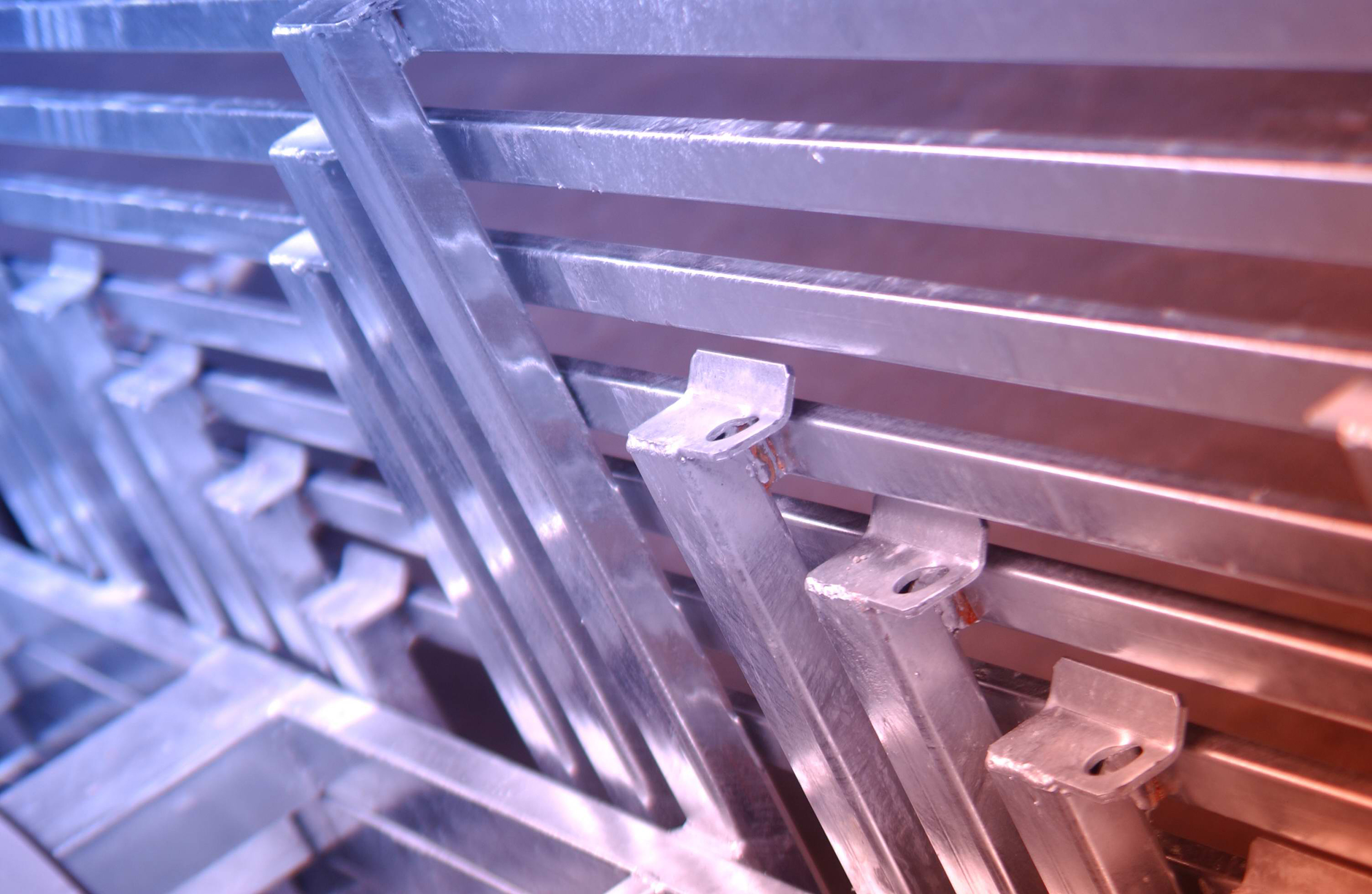

Anodising

Attractive design options & corrosion protection

With perfectly matched products, we ensure the desired gloss or matt etched finish.

From cleaning the surface to sealing, from the contact clamps to sealing covering balls to the post-treatment of anodised surfaces. We provide you with everything from a single source. With us, aluminium becomes a high-performance material, aesthetic and brilliant in form and colour.

Extract from our product range:

Eloxal/Anodisation

Attraktive Gestaltungsmöglichkeiten & Korrosionsschutz

Mit perfekt abgestimmten Produkten sorgen wir für das gewünschte Glanz- oder Mattfinish

Angefangen vom Reinigen der Oberfläche bis hin zum Verdichten, von den Kontaktklemmen über den Sealingball bis hin zur Nachbehandlung von eloxierten Oberflächen. Von uns bekommen Sie alles aus einer Hand. Mit uns wird Aluminium zu einem leistungsfähigen Werkstoff, ästhetisch und glänzend in Form und Funktion.

Auszug aus der Produktpalette:

Our product highlights for anodising:

Cleaner

Etching

Desmutting

Brightening

Anodising additives

Colouring

Sealing-products

Post-treatment products

Other products

Further information is available in our download area.

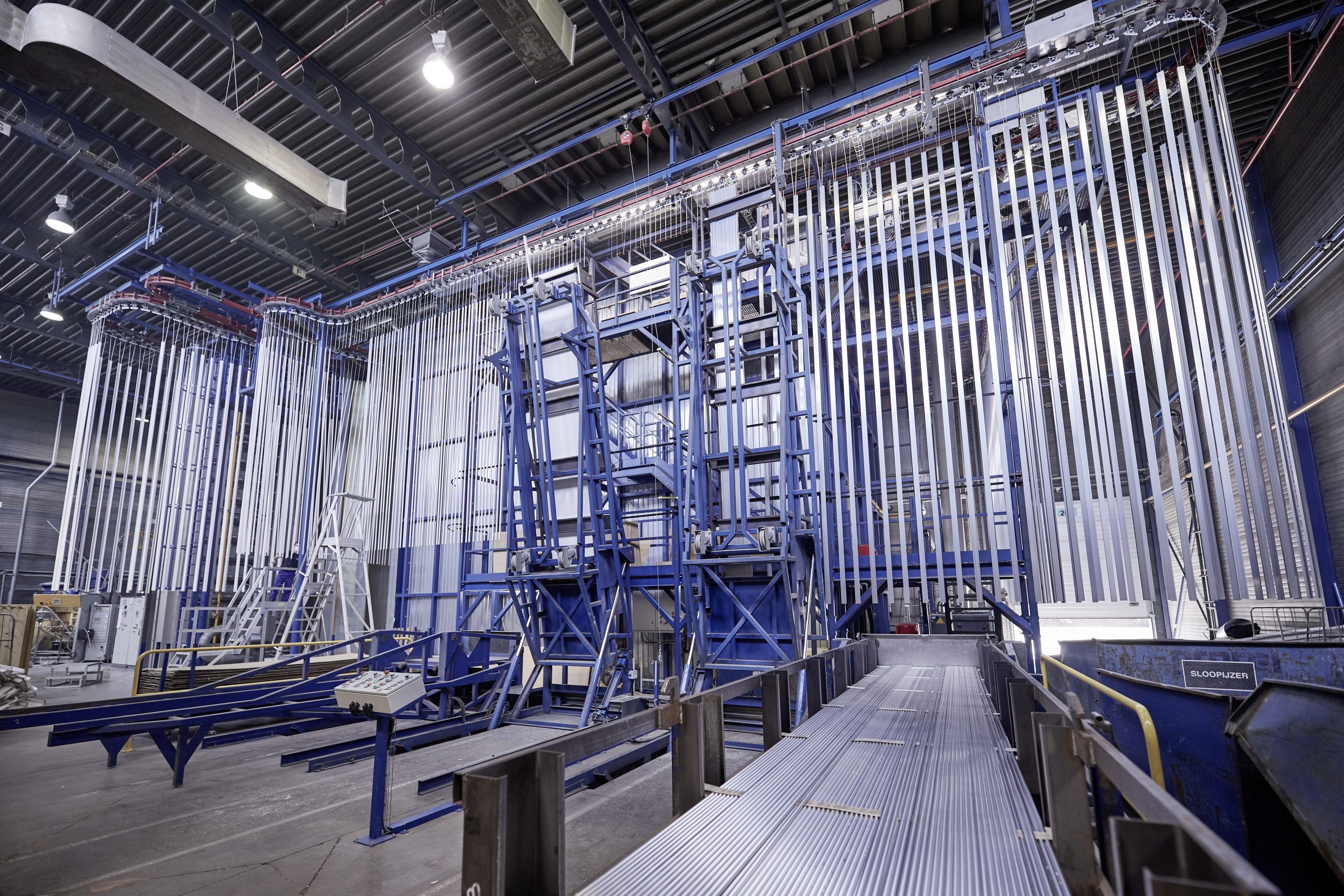

Coating

Pretreatment of aluminium prior to coating

Optimum adhesion and long-lasting corrosion protection

Whether classically chromated or environmentally friendly chromium-free passivated: with our products for pretreating aluminium before the coating process, we ensure that the paint adheres permanently. Whether wet or powder coating, put your trust in the diversity of our product range and our many years of experience and give your customers a long-term promise.

Alufinish - our name is our commitment!

Extract from the product range:

Beschichtung

Vorbehandlung von Aluminium vor dem Beschichten

Optimale Haftung und dauerhafter Korrosionsschutz

Sei es klassisch chromatiert oder umweltfreundlich chromfrei passiviert: mit unseren Produkten zur Vorbehandlung von Aluminium vor dem Beschichtungsprozess sorgen wir dafür, dass die Lackhaftung dauerhaft gegeben ist. Ganz gleich ob Nass- oder Pulverbeschichtung, vertrauen Sie der Vielfalt unserer Produktpalette und unserer langjährigen Erfahrung und geben Sie Ihren Kunden ein langfristiges Versprechen.

Alufinish – unser Name verpflichtet!

Auszug aus der Produktpalette:

Our product highlights for coating:

Weakly alkaline cleaners

Alkaline etching and degreasing

Acidic etching and degreasing

Acid etching

Chromating products

No-rinse

chromating products

Chromium-free passivation

Other products

Further information is available in our download area.

Additional portfolio

Find out more about our wide range of iron and steel and zinc products.

IRON & STEEL

Coating

Phosphating - one process, many possibilities

Phosphating is still regarded as the classic pretreatment of iron and steel surfaces before coating. We offer you a wide range of different products: classic iron phosphating or low-temperature products to efficiently reduce your operating costs. Together with cleaning and passivation systems, we give your steel surfaces the basis for long-lasting durability.

Extract from the product range:

High-performance products with long service lives for cleaning iron/steel surfaces prior to the use of corrosion protection processes.

Liquid additives that act as etching degreasers in combination with acids, e.g. for removing rust and scale

Liquid iron phosphating products for cleaning and phosphating iron and steel materials in immersion and spraying systems. Heavy metal-free variants are also available.

Corrosion protection process for temporary or long-term protection to prevent flash rust during the phosphating process. Chromate-containing or chromate-free alternatives are also available.

Correction solutions, anti-foaming agents, cleaning boosters and system cleaners, flocculants for waste water treatment

Further information is available in our download area.

ZINC

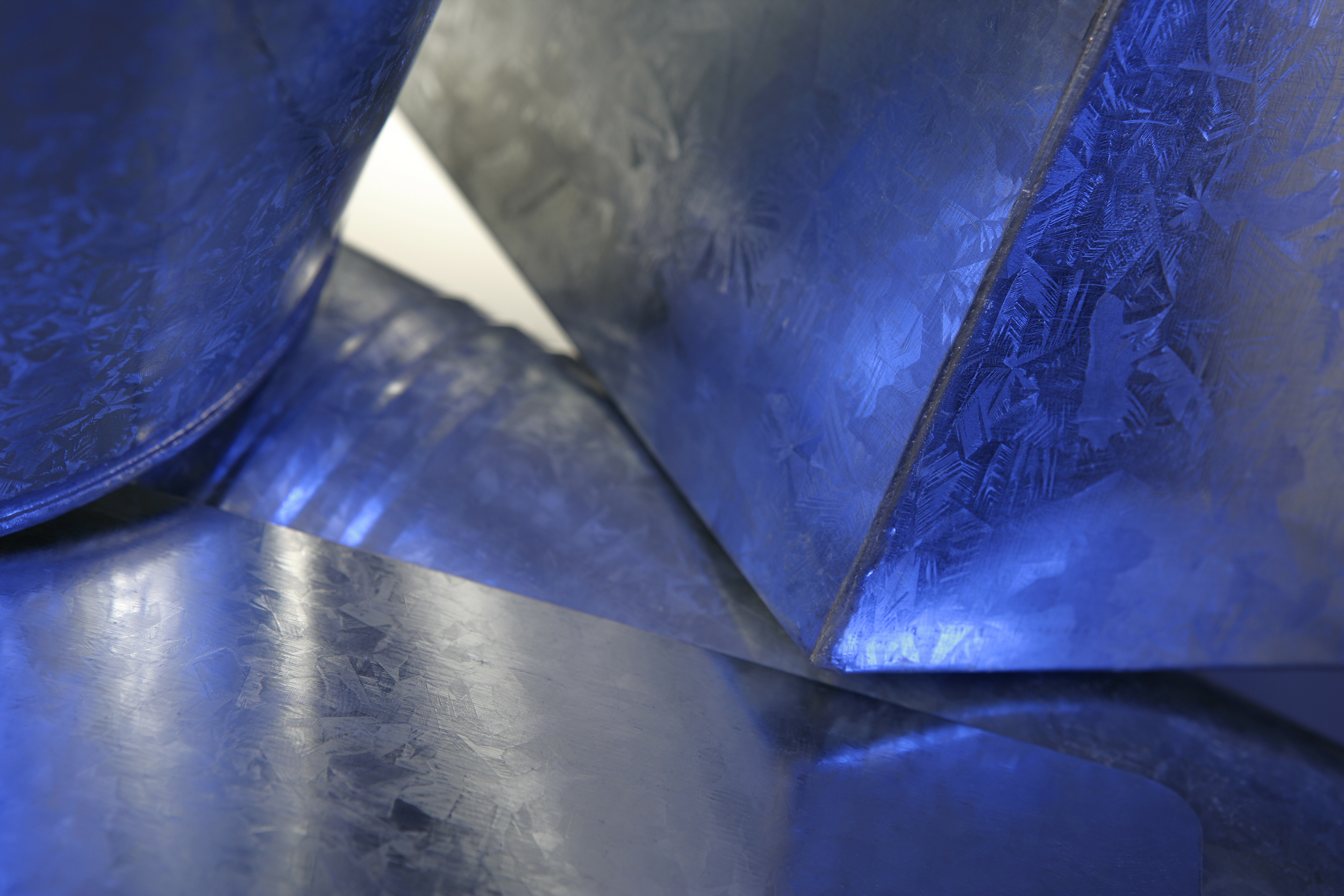

Hot-dip galvanising

Pre- and post-treatment for hot-dip galvanising

Long-lasting corrosion protection down to the smallest corners

Hot-dip galvanising offers comprehensive corrosion protection that lasts for many years. For this to develop optimally, appropriate pre-treatment is required: our alkaline and acidic cleaning systems and special inhibitors ensure this.

Individual processes require individual solutions: we offer them!

Extract from the product range:

High-performance products with long service lives for cleaning iron/steel surfaces before galvanising.

Liquid cleaners and additives that act as powerful etching degreasers in combination with hydrochloric acid. Especially for reducing acid consumption, creaming and etching mists

Highly effective, liquid etching inhibitor for hydrochloric acid and mineral acid etching, to reduce metal removal

Duplex - coating

Numerous special products are available for the pretreatment of duplex systems. This allows you to achieve a wide range of design options and at the same time make an important contribution to environmental protection.

The following process steps are available after galvanising and prior to coating.

Extract from the product range:

Special cleaning system for galvanised surfaces with long service life for dipping and spraying systems

Liquid, acidic cleaners, available as fluoride-free or fluoride-containing variants, 2-component systems for immersion and spray systems; evaporator-compatible variants available

Liquid yellow chromating to improve the corrosion protection properties of galvanised surfaces.

Liquid green chromating to improve the corrosion protection properties of galvanised surfaces.

Liquid, chromium-containing and chromium-free no-rinse and rinse processes for optimising corrosion protection

Further information is available in our download area.

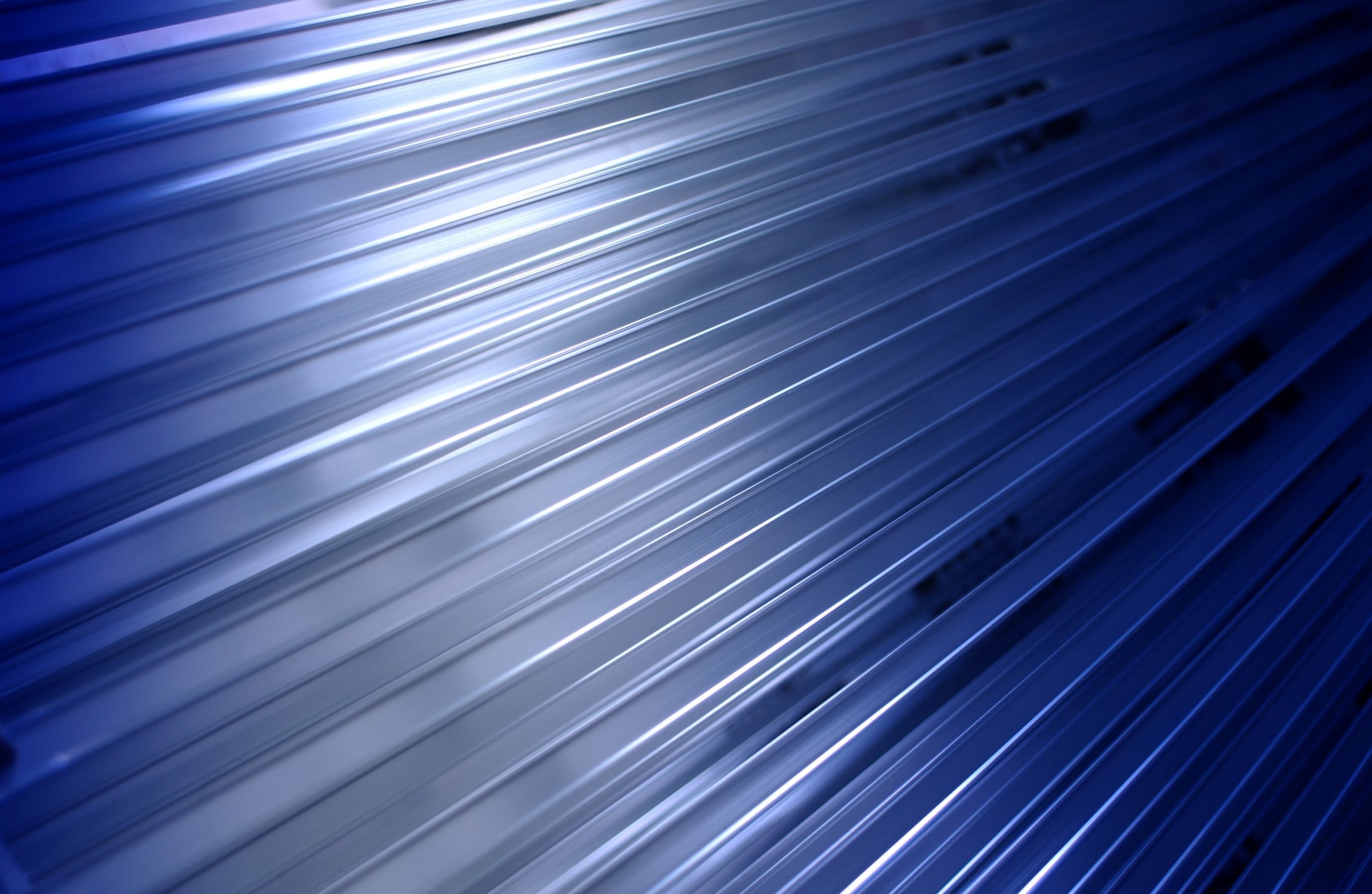

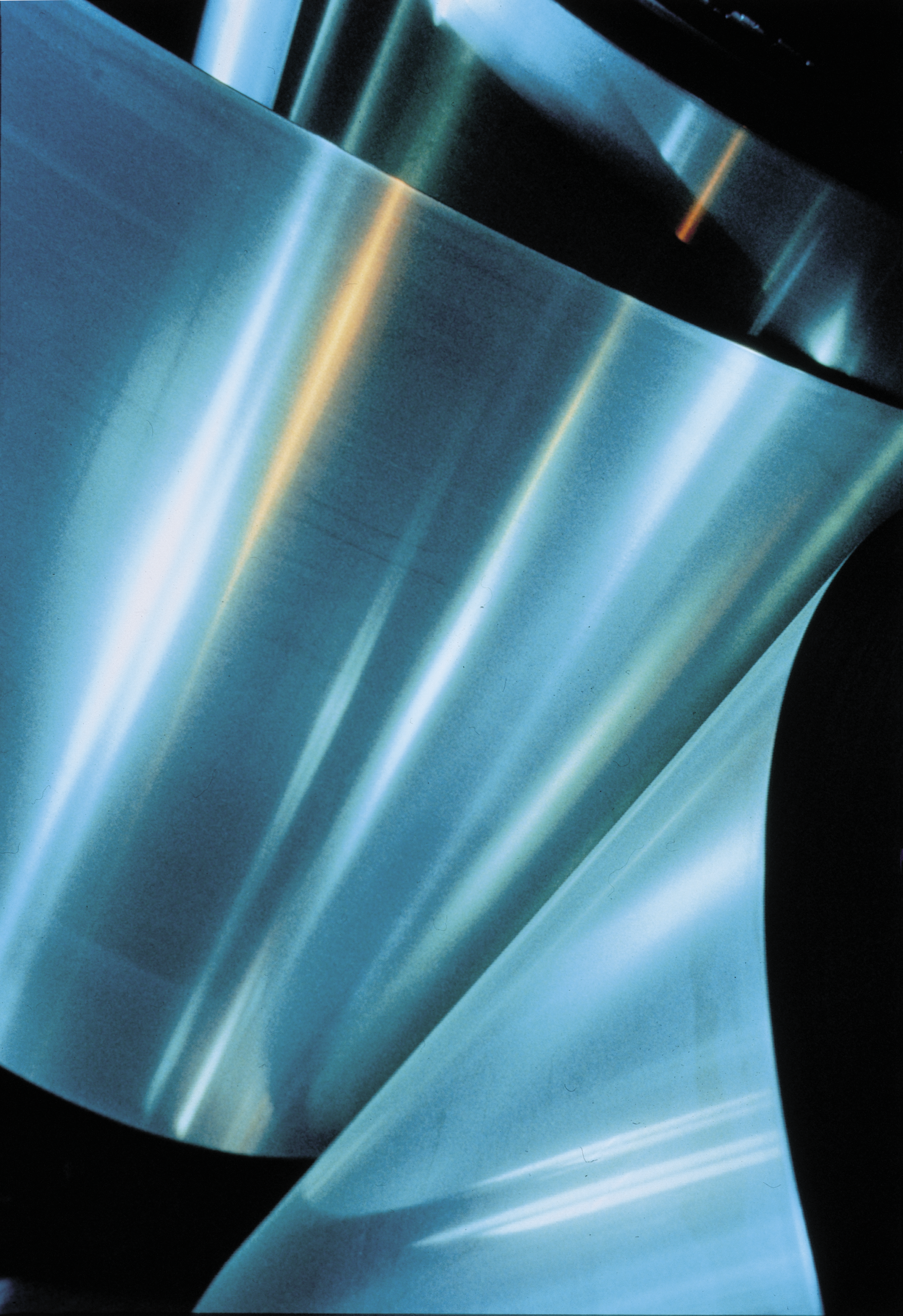

CONTINUOUS METAL COIL COATING

Aluminium coil finishing

Innovative and functional

The right finish for every surface.

Our range of coil finishing products is as varied as the surface and the desired functionality. Regardless of whether it is corrosion protection, decorative stain finish, sealing, colour or forming behaviour.

Extract from the product range:

Liquid, automatically dosed cleaning systems, can be used on aluminium, zinc and steel surfaces

Liquid, for aluminium and zinc surfaces in conveyor systems

Liquid 2-component etching degreaser for aluminium and zinc surfaces in conveyor systems

For etching processes with decorative effect, applicable in aluminium conveyor systems

Further information is available in our download area.