Pretreatment chemistry for anodising and powder coating

Welcome to Alufinish

Alufinish is your proficient partner when it comes to products and processes for the chemical surface treatment of aluminium, steel and zinc. We develop, manufacture and distribute these products from our Andernach site – Made in Germany.

From innovative degreasing agents to chrome-free corrosion protection processes and time-saving hot sealing – we will find the right solution for you.

Together with our international partner network, we have been offering you an extensive product portfolio since 1972, which is used worldwide in numerous anodising and powder coating systems in immersion and spray processes.

Why not contact us? We look forward to hearing from you!

Alufinish – Build on Trust.

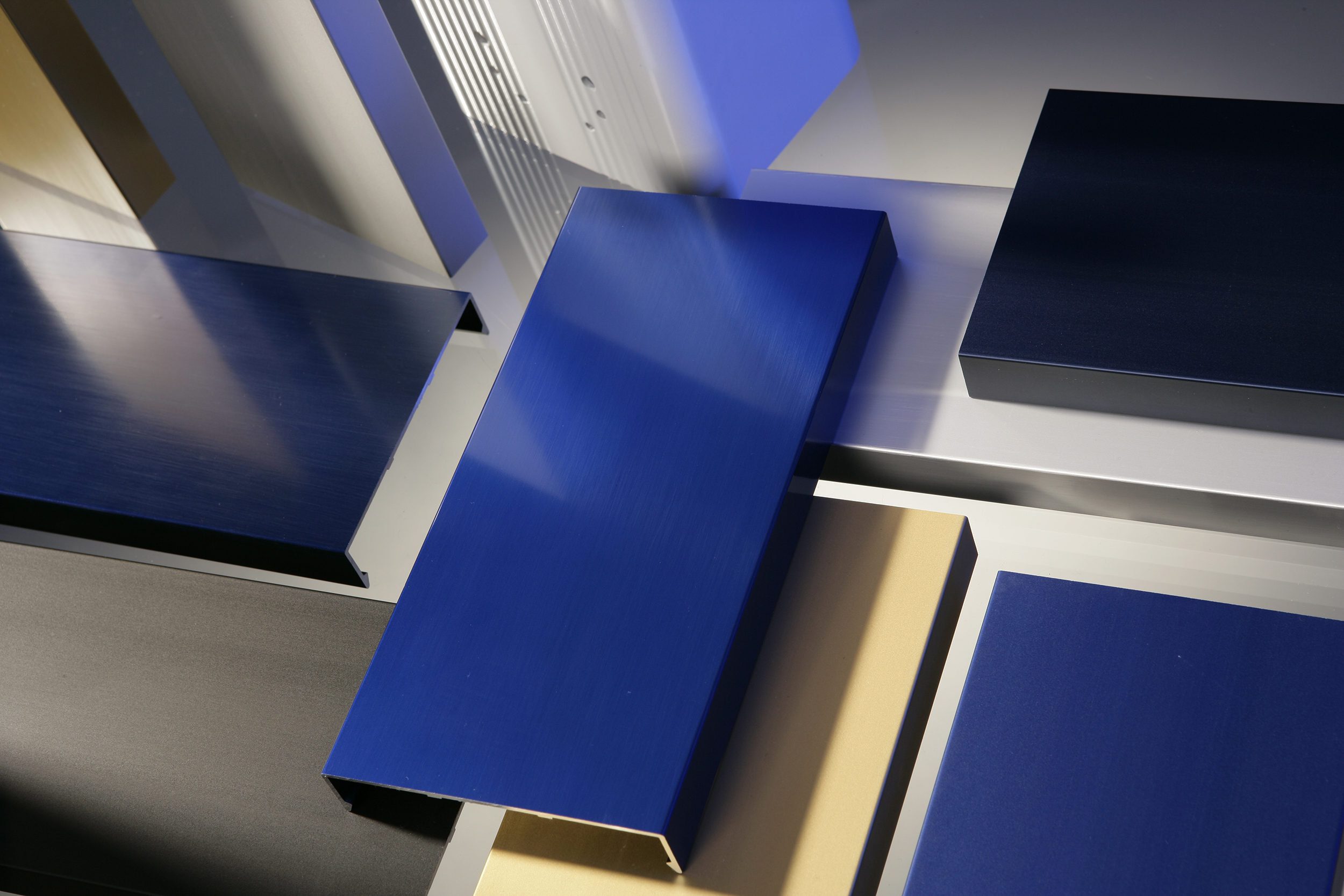

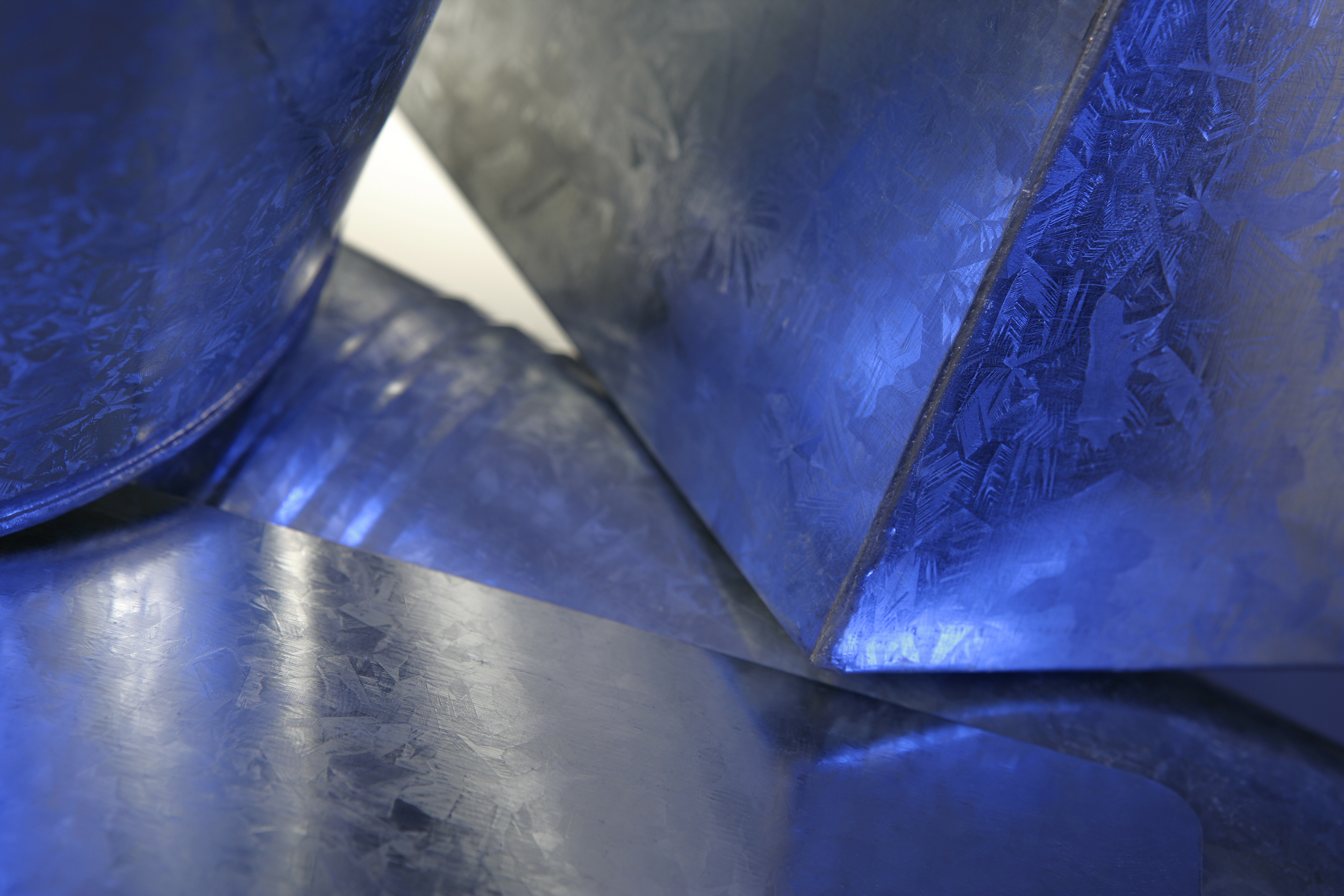

Aluminium

The anodic oxidation as well as special anti corrosion procedures prior to coating offer a variety of attractive design possibilities and guarantee an ideal adhesion and a lasting corrosion protection.

Iron & Steel

Phosphating is still considered to be the classic process for the pretreatment of iron and steel surfaces prior to coating. Apart from this corrosion protection procedure, we also offer various cleaning systems and passivating agents which serve to improve the protective effect on iron and steel.

Zinc

The process of hot dip galvanizing provides a complete and long-year lasting corrosion protection. For an optimal development of this, suitable pretreatment is required prior to the galavanizing process. With special products for the post-treatment of galvanized surfaces, an optimal protection can then be achieved through so-called duplex systems.

Coil refinement

The more varying the metal surfaces, the more challenging the required pretreatment might become. We offer the necessary alternatives for aluminium surfaces, both for simple batch treatment and for continuous coil finishing.

OUR MISSION: YOUR SUCCESS

You are looking for a competent surface refinement partner? Get in touch with us:

Quality that pays off

A quality management system was installed in our organisation at a very early stage.

This system has beencontinuously advanced and made transparent for our customers by certifying it according to DIN EN ISO 9001.

In recent years the requirements on our organisation and our products relating to the fulfilment of statutory regulations have increased significantly as a result of numerous new laws and legislative amendments.

To bear this responsibility, to guarantee the surveillance and realisation of legal requirements and to encourage the ecological awareness of our employees, we have established an environmental management system in our enterprise.

The requirements of EN ISO 14001 have been incorporated in our existing quality management system, resulting in an integrated management system (IMS) that consists of quality, environmental and safety management.

In addition to the already existing quality management system, we have also installed the certification according to DIN EN ISO 14001 so that an integrated management system was formed containing quality management, environmental management and safety management.