Anodising is one of the most established methods for finishing aluminium surfaces. However, even minor deviations in the process can lead to visible defects and non-saleable surfaces. This article outlines three common error patterns – and how to prevent them reliably.

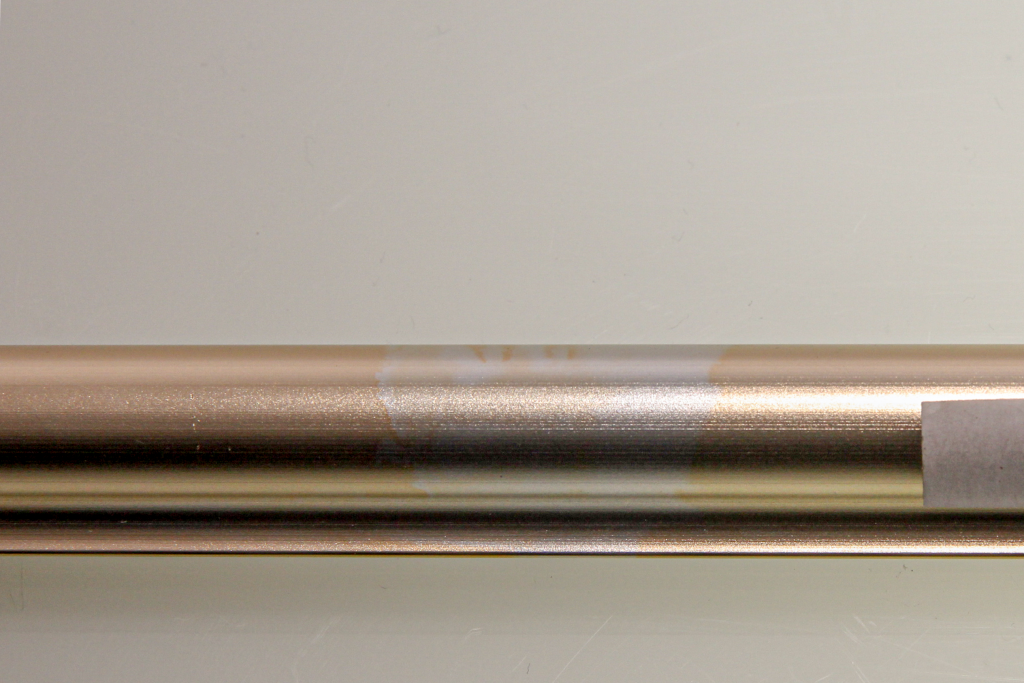

Iridescent Discolouration Due to Contact Faults

After anodising, some components show iridescent rainbow colours for ex. in green, violet or red. These effects are unintended – and indicate insufficient electricity flow during the process.

If the contact point slips during anodising, the current flow is interrupted. Especially once a non-conductive oxide layer has formed, no further oxide growth can occur. The result: uneven, very thin oxide layer thicknesses with visible discolouration.

Secure and stable contact is essential – especially for large or thin components. Airflow in the anodising bath should also be optimised to avoid excessive turbulence, which may lead to shifting the goods during the process.

Run-Off Marks After the Anodising Process

Streaks or bright marks – particularly on coloured or brightened surfaces – often appear during the transfer of the parts after the last process bath (hot sealing)

Contaminants on the carrier frame, particularly from old bath residues or acidic/alkaline condensation, may dissolve due to steam during lifting and drip onto the finished parts. There, they lead to drainage marks and, in some cases, discolouration.

Carrier frames should be cleaned regularly, either manually or automatically – ideally integrated into the process. A dedicated rinse bath for the product carrier beams before sealing can be an effective preventative measure.

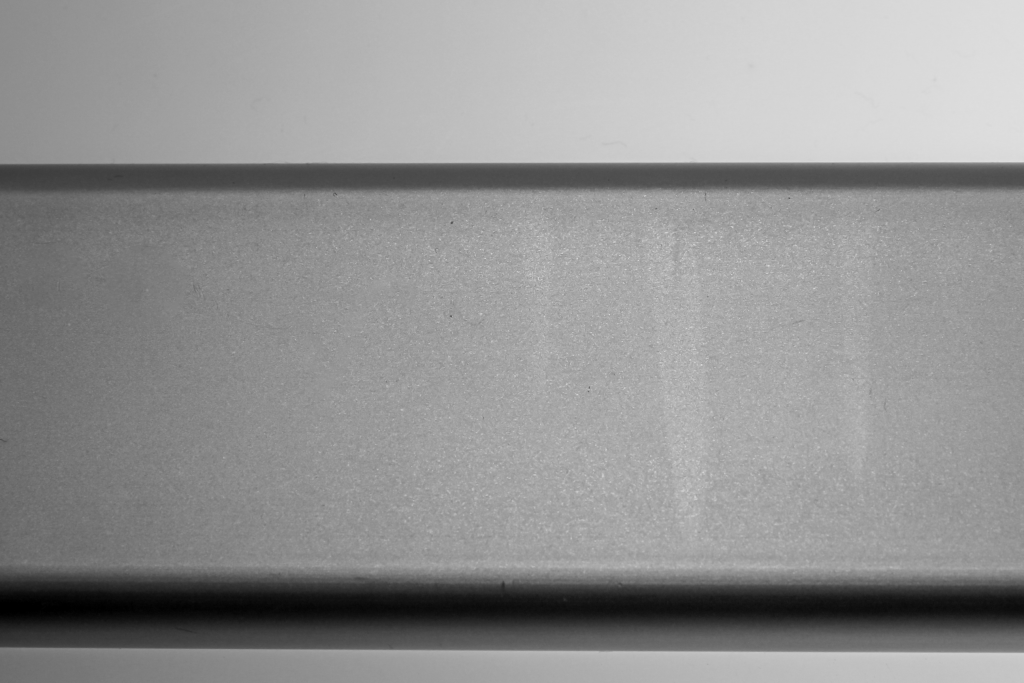

Patchy Surfaces Caused by Adhesive or Foil Residues

Uneven, patchy or relief-like surface structures regularly occur when adhesive residues or protective films remain on the aluminium surface during pretreatment.

These residues or remaining foil residues prevent uniform etching. Only once they are fully removed does the etching process begin – with visible imperfections on the final product.

Before chemical pre-treatment, the material should be checked for residues and, if necessary, pre-cleaned with suitable solvents. Particular attention should be paid to edges, recesses and corners.

Summary

From contact reliability to equipment cleanliness and surface preparation – every detail matters in anodising. The defects outlined above clearly demonstrate the importance of consistent process control and simple preventative measures. Only with this approach can high-quality, reliable anodised finishes be ensured in the long term.