Besides the daily self-monitoring in powder coating companies, various quality associations also require regular corrosion tests at the chemical manufacturer or in institutes.

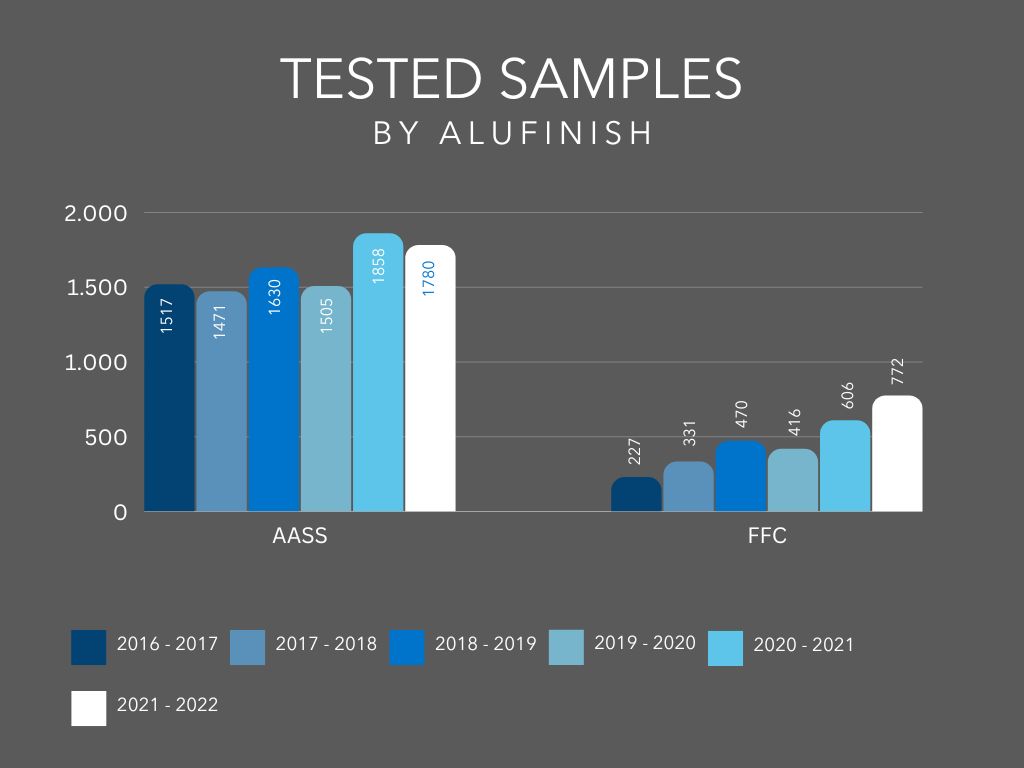

Tests are important in order to be able to control and guarantee consistent surface quality. In order to meet the large number of test specimens that have to be tested at Alufinish, the capacity of the test chambers had to be significantly expanded for this purpose in recent years. Today, 3 chambers with a test chamber volume of 2500 liters are available for these testing purposes for the acetic acid salt spray test (AASS) alone. These chambers are also constantly occupied throughout the year. The number of samples to be tested in the filiform corrosion test (FFC) has also increased significantly in recent years.

In addition to the actual inspections, the time required for receiving notification, evaluation and inspection report documentation should not be underestimated. The entire testing process is handled as part of Alufinish’s proven customer service.

Do you have any idea how many samples are up for review each year?

The following statistics provides the answer:

The evaluation period in the table refers in each case to examinations from September – August of the following year.

Considering the other tests carried out, such as humidity and neutral salt spray test, the total number of tests carried out in 2021 – 2022 is 3308. Of these, about 54% are then accounted for by the AASS and 23% by FFC, and another 23% by the other tests.