Electrolytical colouring with tin salts has been a popular process in anodising operations for decades. It can be used to produce numerous variants of bronze colourations (light to dark bronze), but also black surfaces on the aluminum base metal. While bronze shades were mostly predominant in recent decades, the process is now often used for pure black colouring.

The amount of tin deposited on the bottom of the pores by means of alternating current determines the intensity of the colouration. In conjunction with a correctly executed sealing process, the colourations are generally considered to be resistant to light and weathering and allow well reproducible results in operation. No wonder, then, that colouring with tin salts is widely used in both the architectural and automotive sectors. At Alufinish, the associated product portfolio is marketed under the process designation Tin-ColorAL – process.

“Cold” or “warm” black tone?

However, there are also special requirements, for example in the automotive sector, where the purpose is to produce black colours that are as neutral as possible (often also “cold”). So it is necessary to avoid that the black colour produced appears brownish (“warm”) instead. A difference is typically only visible if the correspondingly coloured goods are viewed directly next to each other under standardised light.

Colour effects can also be influenced to a certain extent by modifying the anodising conditions and the colouring bath temperature, as well as the DC-AC control. But also by choosing the right Alficolor stabiliser, the colour effect can be shifted in the desired direction. For this purpose, it is worth taking a look at the product portfolio for the Tin-ColorAL process.

| The Tin-ColorAL product portfolio | Attributes |

| Alficolor 677 | Ready-to-use product for “neutral” black colouring; Main product |

| Alficolor 673 | Ready-to-use product especially for „cold“ black colouring |

| Alficolor 679/2 | Ready-to-use product especially for „warm“ black colouring |

| Stabilisers (without tin) | |

| Alficolor 697 | Main stabiliser for „neutral“ black colouring providing a very good depth scattering |

| Alficolor 693 | Special stabiliser for „cold“ black colouring; providing a good depth scattering |

| Alficolor 699 | Special stabiliser for optimising depth scattering conditions in the colouring bath; Providing a „warm“ black colouring |

| Tin(II)-sulphate | |

| Liquid | Tin(II)-sulphate solution |

| Solid | Tin(II)-sulphate crystalline |

For most applications, the use of Alficolor 677 or tin(II)-sulphate with the stabiliser Alficolor 697 is suitable. Special colour effects (“warm” or “cold”) can be achieved by changing to a special Alficolor ready-to-use product or stabiliser. Thanks to the compatibility of all Alufinish stabilisers with each other, a change from “warm” to “neutral” to “cold” is possible at any time and back again.

Important – the bath conditions

For achieving adequate colouration, the condition of the bath is of considerable importance. Relying only on the correct content of tin(II)- sulphate, sulphuric acid and stabiliser can still result in insufficient colouration. In addition to contacting and current conditions, this can also be due to impurities or insufficient depth scattering in the bath.

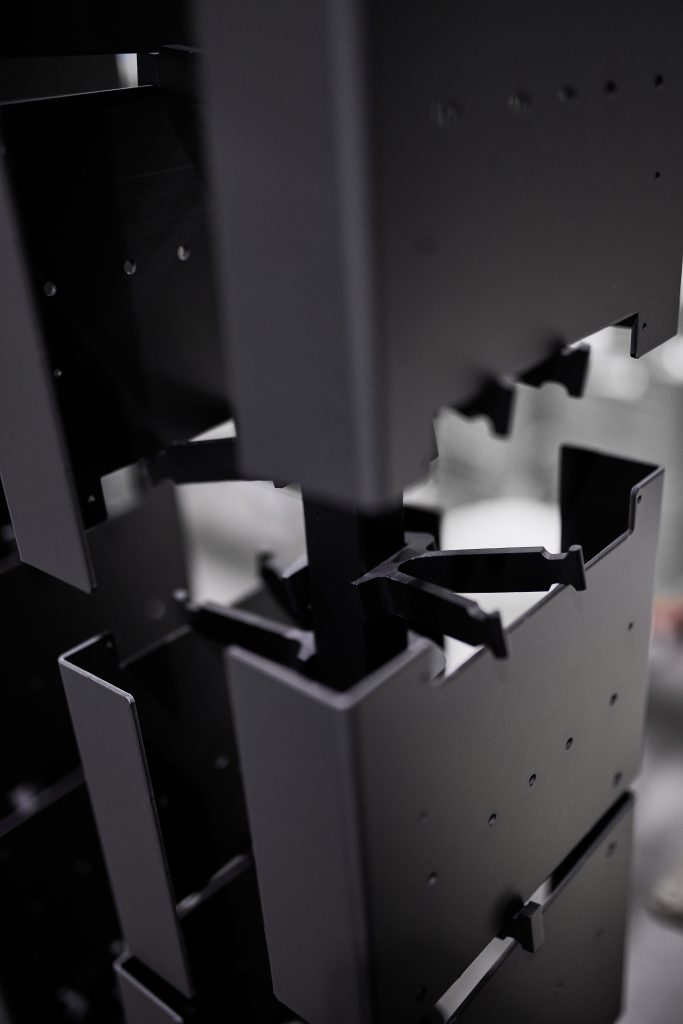

Good depth scattering results in uniform, intensive colouring of the aluminum on the rack. Since the depth scattering cannot be determined analytically, a special laboratory test is carried out at Alufinish with the respective colouring bath solution. This enables a reproducible statement to be made about possible interfering impurities (such as nitrates) and the depth scattering behavior of the bath solution. Due to the high informative value of the test, specific measures can then be taken to eliminate interfering ions (e.g. by adding Correction Solution 600) or to optimise the depth scattering by means of suitable Alficolor stabilisers. In this way, a colour bath solution that has not been optimally adjusted can usually be quickly converted back into a functional one.