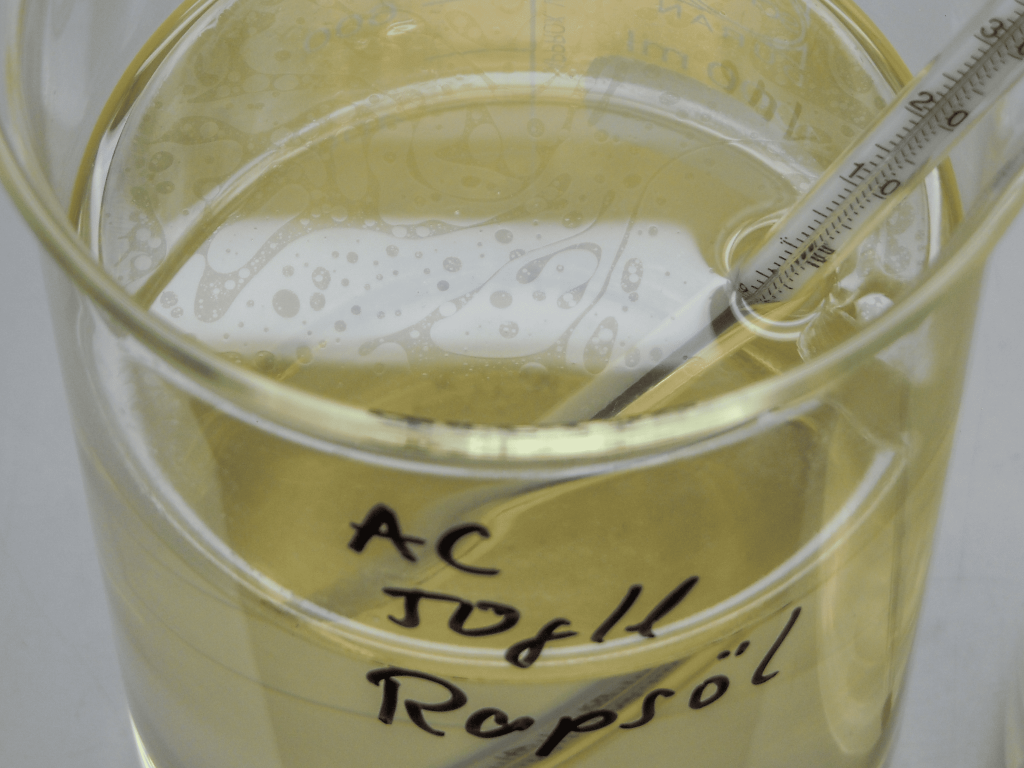

In addition to the use of renewable raw materials for the production of biofuel, native oils, such as rapeseed oil, are increasingly being used in metal processing, for example for lubrication or for oiling surfaces. However, this often leads to problems, as these oils often cannot be removed in classic, weakly alkaline cleaners. The traditional focus of many formulations on cleaning synthetic oils and greases often leads to massive cleaning problems in pretreatment operations when “bio-oils” are suddenly used. As a rule, the company does not notice this for incoming goods, as the difference is not visible on the oiled surface. However, strange optical effects can often be observed in the cleaning bath:

Therefore Alficlean 1165

Alficlean 1165 was developed to offer a solution to the problems faced by companies that are frequently confronted with bio-oils. This weakly alkaline cleaner is a low-salt, liquid cleaning combination designed for immersion systems. Stubborn oils and greases, such as polishing pastes and bio-oils, can be effectively removed after just a short reaction time. Of course, it is also possible to remove synthetic oils, which can then be carried out at a significantly reduced concentration and temperature. The application otherwise corresponds to the usual cleaning conditions and concentrations. In the case of polishing pastes, the temperature can also be increased to 70°C if necessary without any significant loss of gloss.

But Alficlean 1165 has even more advantages:

-

- It is borate-free

-

- It is phosphate-free

-

- It is low in salt content

-

- It can be dosed automatically

-

- It can be analysed photometrically

Alficlean 1165 thus represents an interesting further development of the familiar Liquipower generation of cleaners.