A common problem in anodising operations: The goods have been chemically pretreated and when the flight bar is transferred to the removal station, you suddenly notice clearly visible drain off marks on the surface that cannot be wiped off. In some cases, colour lightening is even visible on appropriately coloured goods. Goods damaged in this way are not fit for sale and must be reworked.

There can be many reasons for such run-off marks in anodising operations

- Already caused by pre-corrosion on the raw material

- Due to inadequate rinsing technology after etching and polishing processes

- Drying of process liquids due to excessively long draining times

- Drain off marks due to incorrectly adjusted hot sealing baths, etc.

However, the simple separation of process bath liquids or mists on the flight bar can also be a cause of defects. In particular, the finest etching mists that form during E6 or E0 etching, polishing and anodising are deposited on the flight bar surface. These are preferably concentrated on the underside of the flight bar. Alkaline residues are partially neutralised by subsequent acidic bath mists, become encrusted and remain there until the hot sealing process is complete. When the flight bar with the goods is lifted out, these are then dissolved again by the bath mists (hot water vapour) and the aggressive mixture drips off over the finished product. Depending on the quantity, pH value of the mixture and its exposure time on the surface, more or less visible drain off marks appear on the goods or on their edges. Reworking is usually the result.

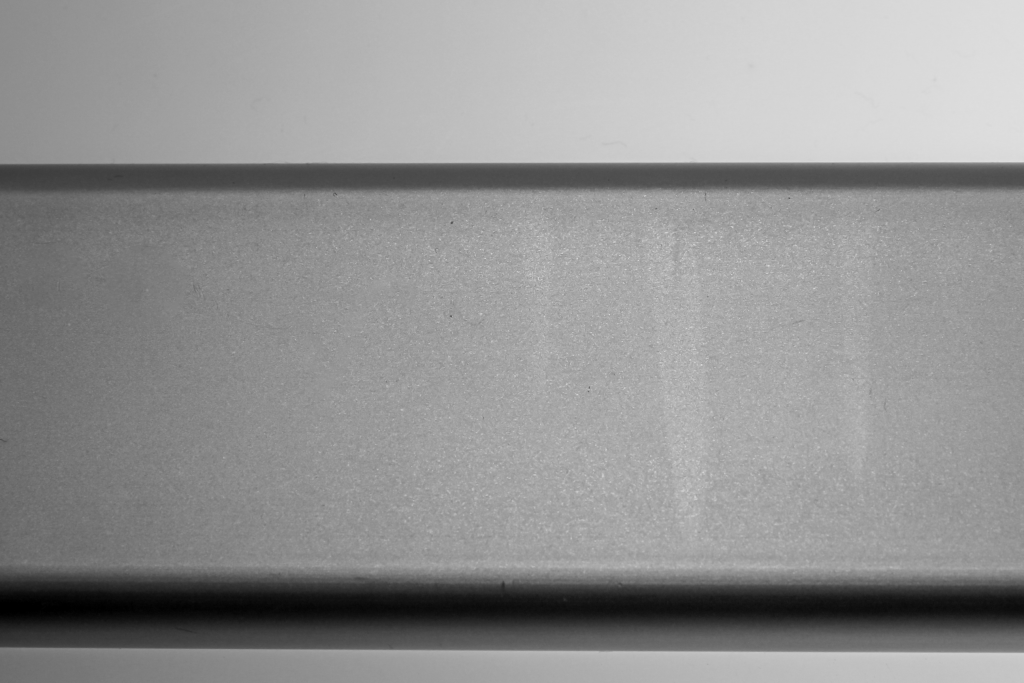

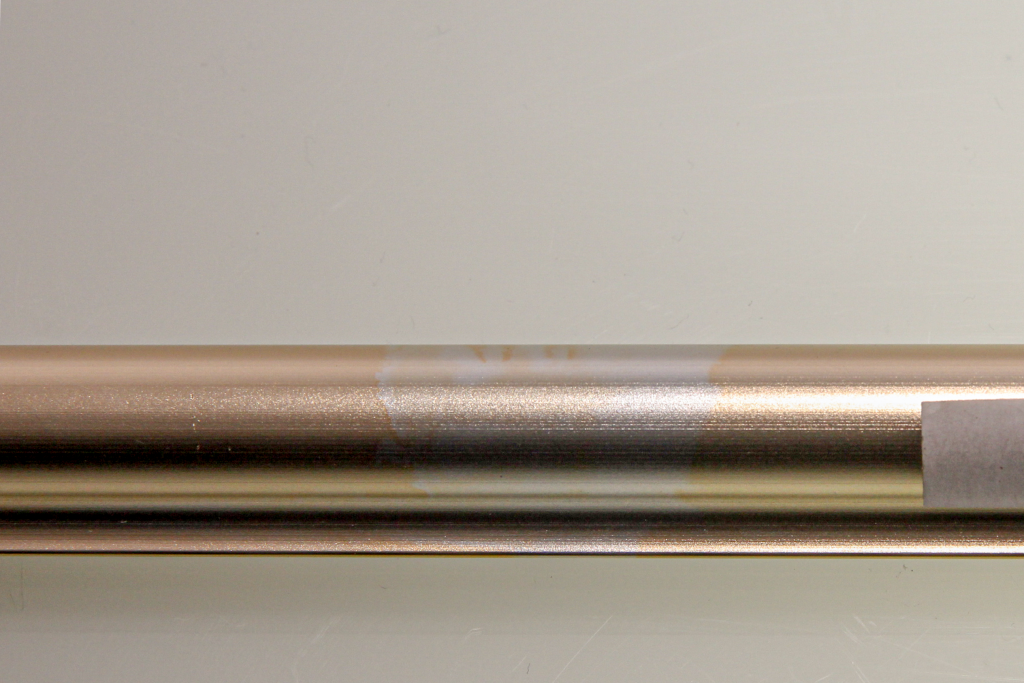

The comparison of soiled and clean flight bars illustrates the source of error

How can you avoid the problem?

A straightforward solution addresses the issue. Regularly rinsing the flight bars with water effectively eliminates any residue. This can be carried out manually, for instance, by spraying them (using a water hose) over the rinsing baths. In cases of persistent build-up, sometimes only mechanical grinding of the flight bar surface proves effective. Nevertheless, automated cleaning within the process is also feasible provided the system is appropriately designed. The following example illustrates the cleaning process of the entire product carrier bar in a rinsing bath during pre-treatment.