Advantages and practical application of Alufinish Liquipower cleaner

The question arises why a change from a solid cleaner to a liquid cleaner should be considered, especially if the previous cleaning solution already provides satisfactory results. Concerns are often expressed that liquid cleaners contain more chemicals. However, there are distinct advantages to using liquid cleaners compared to solid variants.

Liquid cleaners can have important advantages compared to solid cleaners

The most important argument is that the cleaning properties of Liquipower have improved compared to the solid cleaners. Liquids can contain surfactant combinations that are not possible in the solid versions. The concentrations of the liquid cleaners have “improved” too. The standard concentration of the Liquipower family is as it is for the solids, 40 – 60 g/l, where it used to be 50 – 100 g/l.

Another very important advantage of the Liquipower cleaners is, that the surfactant combinations provide improved degreasing properties. Together with other ingredients this causes a longer, stabile suspension of solids and bonding of oils in the solution. As a result, the lifetime of the cleaner is extended with a two-, or in some cases even a threefold! As a cleaner will never be without grinding residues, dirt, and solid suspensions, Liquipower will become turbid in time too. This sludge can be cleaned out easily by regular maintenance.

“But that is what I would do with a solid cleaner”! Yes, you would. The Liquipower however, contains no fillers! Fillers are a matter that has no other functionality than solidifying components in the cleaner. Some of them will deposit at the bottom of the tank while making up, and they will cause white incrustations on the tank walls and the heating tubes throughout processing. Liquipower will keep the installation clean and your heating system effective. Liquipower will in time even clean out the existing incrustations caused by fillers, giving the inside of the cleaner tank the outlook of the tank as if just installed.

The metal removal by etching in the Liquipower cleaners has also improved. It has been brought down to < 1 g/m2 in 15 minutes (50 g/l Alficlean 152, 60 °C, alloy 5005). The fact that there is way less dissolved aluminium in the cleaning solution helps to extend the lifetime. Liquipower has a broad temperature range and works very efficient up to 75 °C. This could be of great help to cleaning buffing paste from the aluminium surface, while keeping the gloss level at the highest level possible. This opens a wide range of applications for the Liquipower. Besides the common applications of anodising and pretreatment before coating, Liquipower can be applied in continuous can and tube cleaning lines.

The application is decisive for the chosen version of cleaner, spray, or immersion. Sprayable Liquipower cleaners will be practically foam free in all applications. Addition of defoamers, extra renewal of rinses, foam skimming from the surface, they are all history. In combination with the Alfisatin technology, Liquipower will also reduce foam on the alkaline long-life etch.

The monitoring capabilities of a cleaner were, beside the optical evaluation (water break, markers, or inks), often limited to the salt concentration. This method is okay for a cleaner with low throughput, but will start varying when alkalinity is brought to the cleaning process. From that point and by titration, the concentration of the cleaner will go in every direction. Liquipower has eliminated this phenomenon. Addition of a specific component in the product has made it possible to analyse the product by spectrophotometer. This method is, also in the long term, very reliable and accurate.

The last reason to choose for liquid cleaners is obvious, as they come in dissolved and can therefore be simply, automatically dosed in the process tank by a dosing pump. This provides a simple process management and avoids lows and highs in the product concentration.

Practical example dip application

Changeover to Alficlean 152 – Anodising line (Tank volume: 11 m³, Throughput: 1.5 m²/year):

| Product | Features | Cleaning interval/ Control |

| Solid cleaner | – Oil skimmer – Filtration system – Process time for grinded aluminum: 15 min | Every 4 – 6 weeks, desludging of the solution |

| Alficlean 152 liquid | – Never dump mode over drag-out (balancing of water loss and dosing) – No filter, skimmer – Process time for grinded aluminium: 10 min | Routine control 1 x year and on dropped parts |

Practical example spray application

Changeover to Alficlean 169 – Can cleaning line.

(Two-step process with pre- and post-cleaning), Throughput: 100 – 200 cans/min

| Product | Features | Cleaning interval |

| Strong alkaline | – Strong incrustation of the line – Extreme foaming – High aluminium content | Weekly |

| Alficlean 169 | – Clean line components – No incrustations – Low aluminium content – Foaming under control – Enhanced cleaning | Every 6 – 8 weeks |

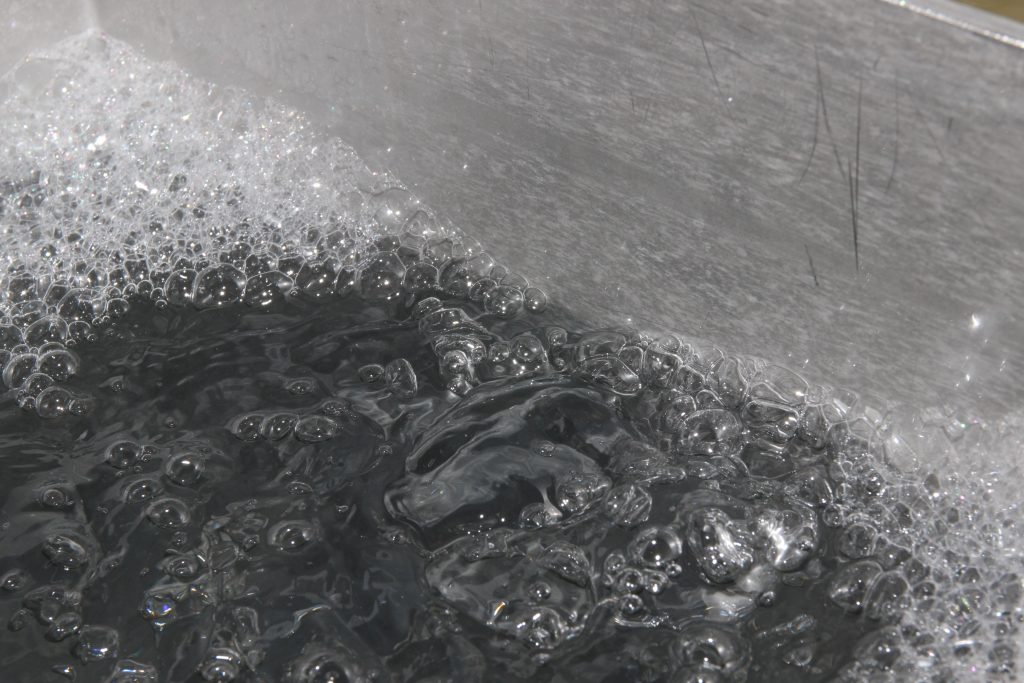

Before changeover – strong alkaline cleaner – High foaming

After changeover – Alficlean 169 – Controlled foaming

Changing to VOC-free paint system and the therefore higher demand for a clean surface, Alficlean 169 has confirmed its value. Production tests have confirmed the improvement of the cleaner surface, so for Alficlean 169 there are no more restrictions.

An important criterium, developing Liquipower was the environment. Part of the focus was on development of borate-free versions. Borate-free versions are available for all Liquipower products.

Liquipower products – an overview

| Product | Features | Application |

| Alficlean 152 | – Multipurpose application – Borate-free – Low metal removal – Lifetime extension – Compatible with Alfisatin alkaline etch | Dipping for anodizing and pretreatment |

| Alficlean 150 | Mildly alkaline with light metal removal Focus on cleaning buffed surfaces | Dipping for brightening processes |

| Alficlean 169 | – One component – Borate-free – Extreme low foaming – Low metal removal – For continuous high throughput – Gloss remains | Spray, for example can cleaning |

Liquipower liquid cleaners make the work with the chemicals easier. Dosing, shorter process time, never-dump and enhanced analytics all support to an efficient process.