Even small mistakes while cleaning aluminium surfaces can lead to unsaleable goods in the anodising plant. It is therefore always worthwhile to take a look at the raw material that is about to be pretreated. If there are still residues of adhesive tapes or protective films on the surface, these will most likely be visible as stains on the final product. As a consequence, unnecessary rework will result.

Using the example of adhesive tape residues:

In the Alufinish laboratory, the extent to which a mildly alkaline standard cleaner is capable of removing adhesive tape residues was simulated. For this purpose, a component contaminated with adhesive tape residues was cleaned under the following conditions:

Concentration: 50 g/l

Temperature: 55 – 60°C

Cleaning time: 15 minutes

Immersion test with air injection

This was followed by matting in an alkaline long-term etching (E6) – desmutting – anodising and sealing.

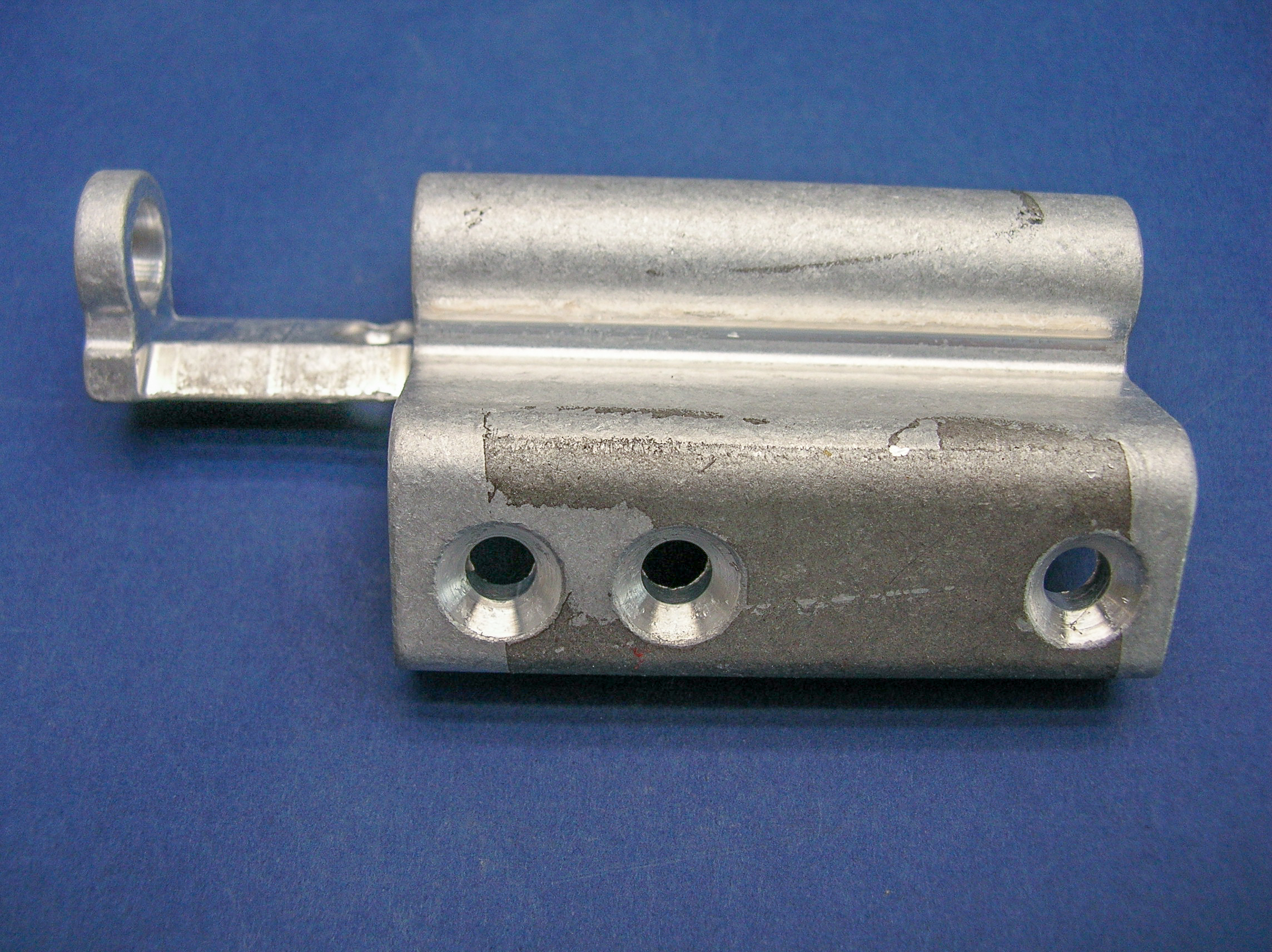

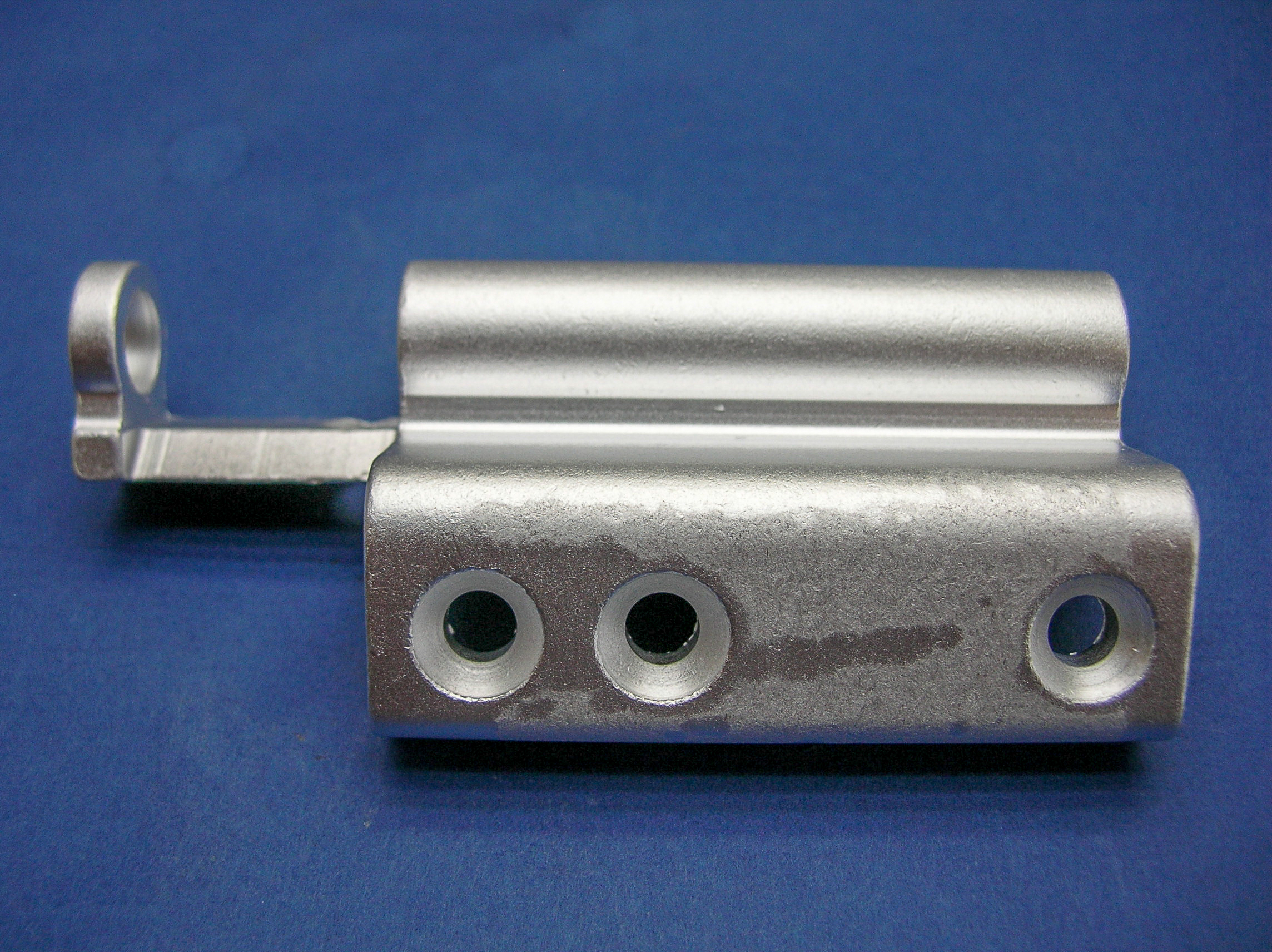

Raw material before cleaning

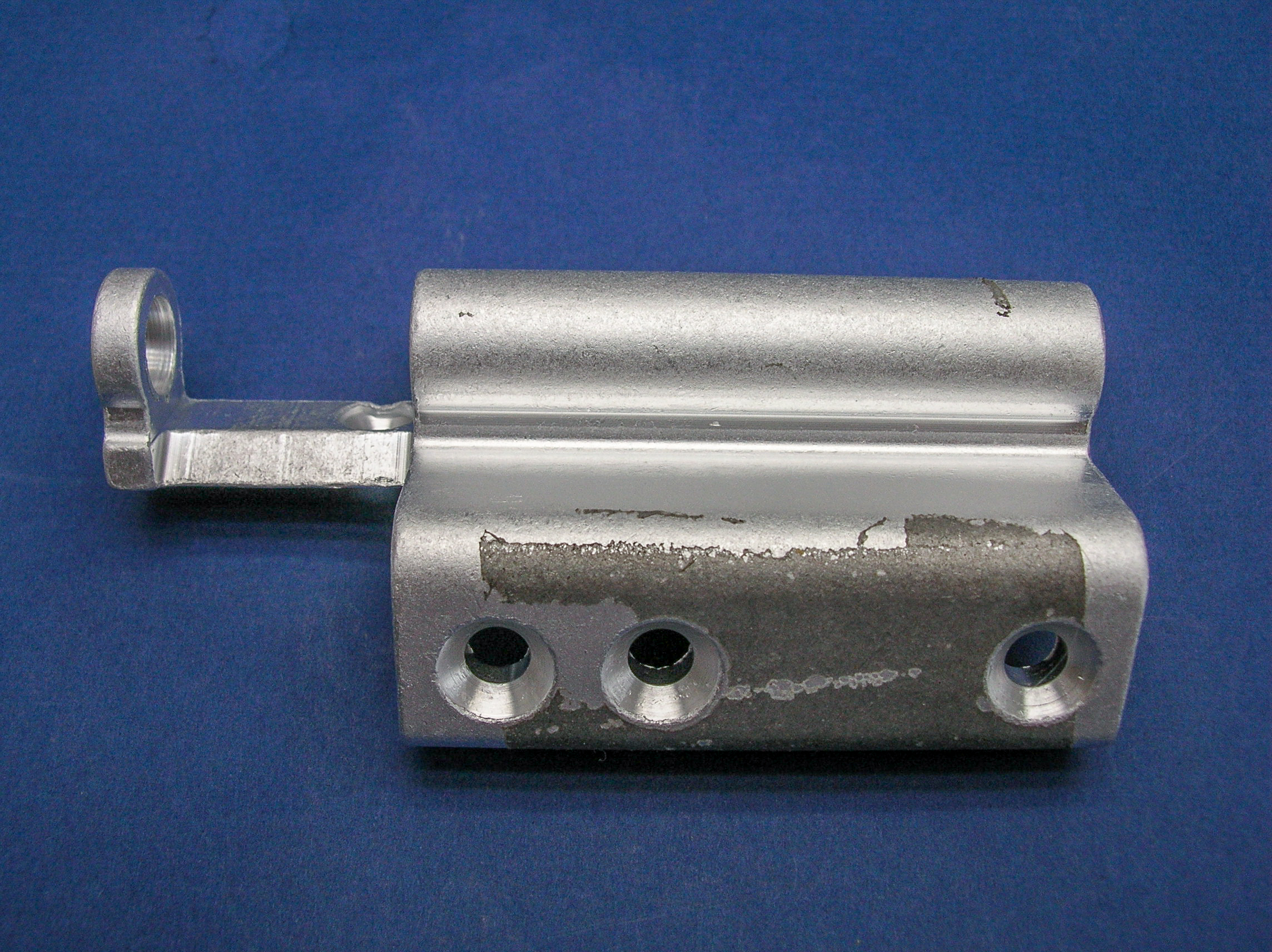

After 15 minutes of cleaning time

Even after this cleaning time, almost all residues are still present on the surface. A mild-alkaline cleaner is therefore not able to remove these stubborn adhesive residues.

Now it was simulated what happens when this material is transferred to the alkaline etching (E6) unattended.

After 10 minutes pickling in an alkaline E6 etching bath:

Only insignificant amounts of adhesive residue have been removed.

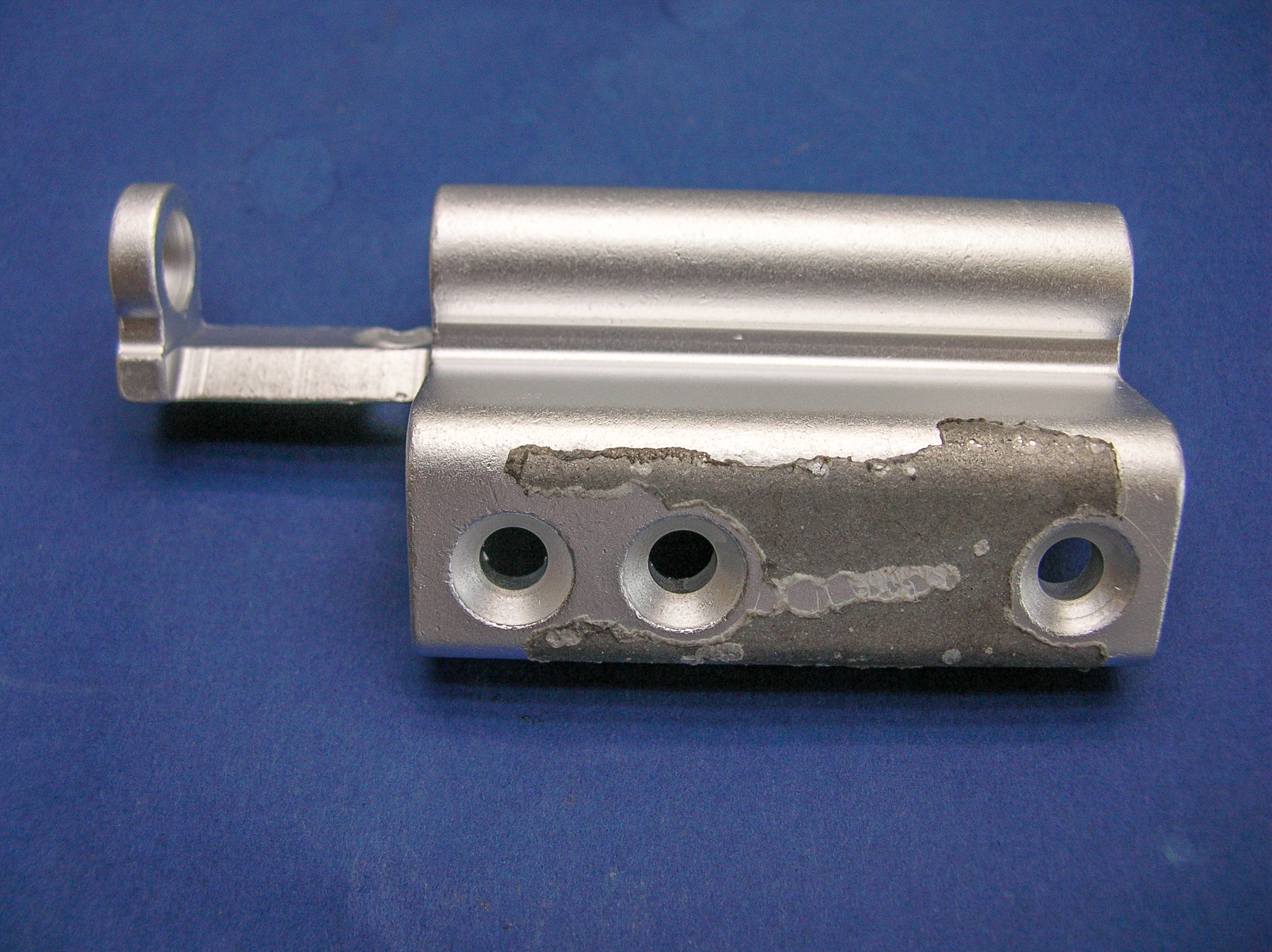

After 15 minutes pickling in an alkaline E6 etching bath:

The adhesive tape residues are removed, only now the pickling process begins on the cleaned areas.

Component at the end of the pickling time (here: 18 minutes).

While the main surface was uniformly matt-stained, the surface with the former adhesive tape residues appears stained. The stains cannot be removed by the subsequent process steps and are also visible on the final product.

Why does this error pattern occur?

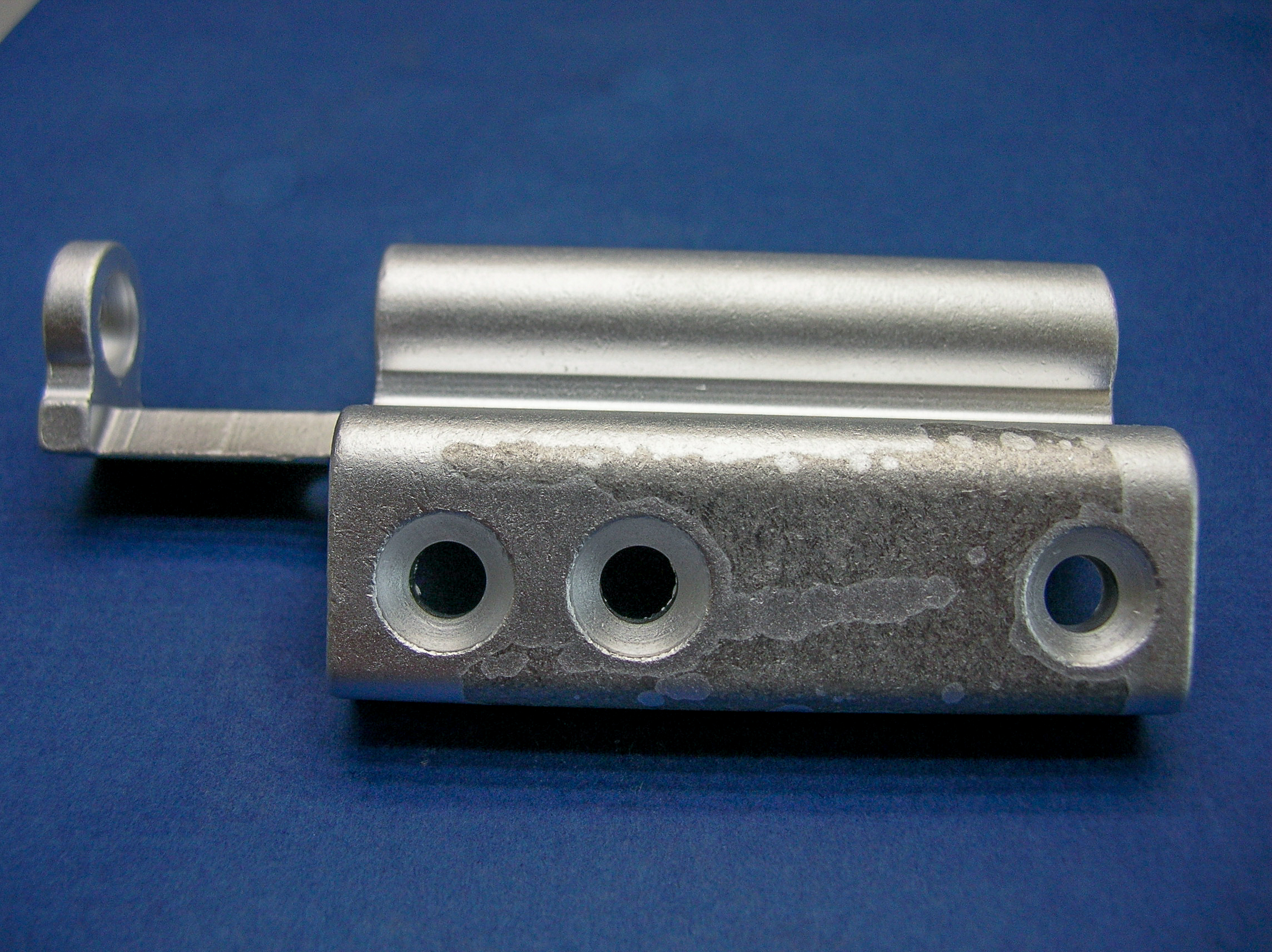

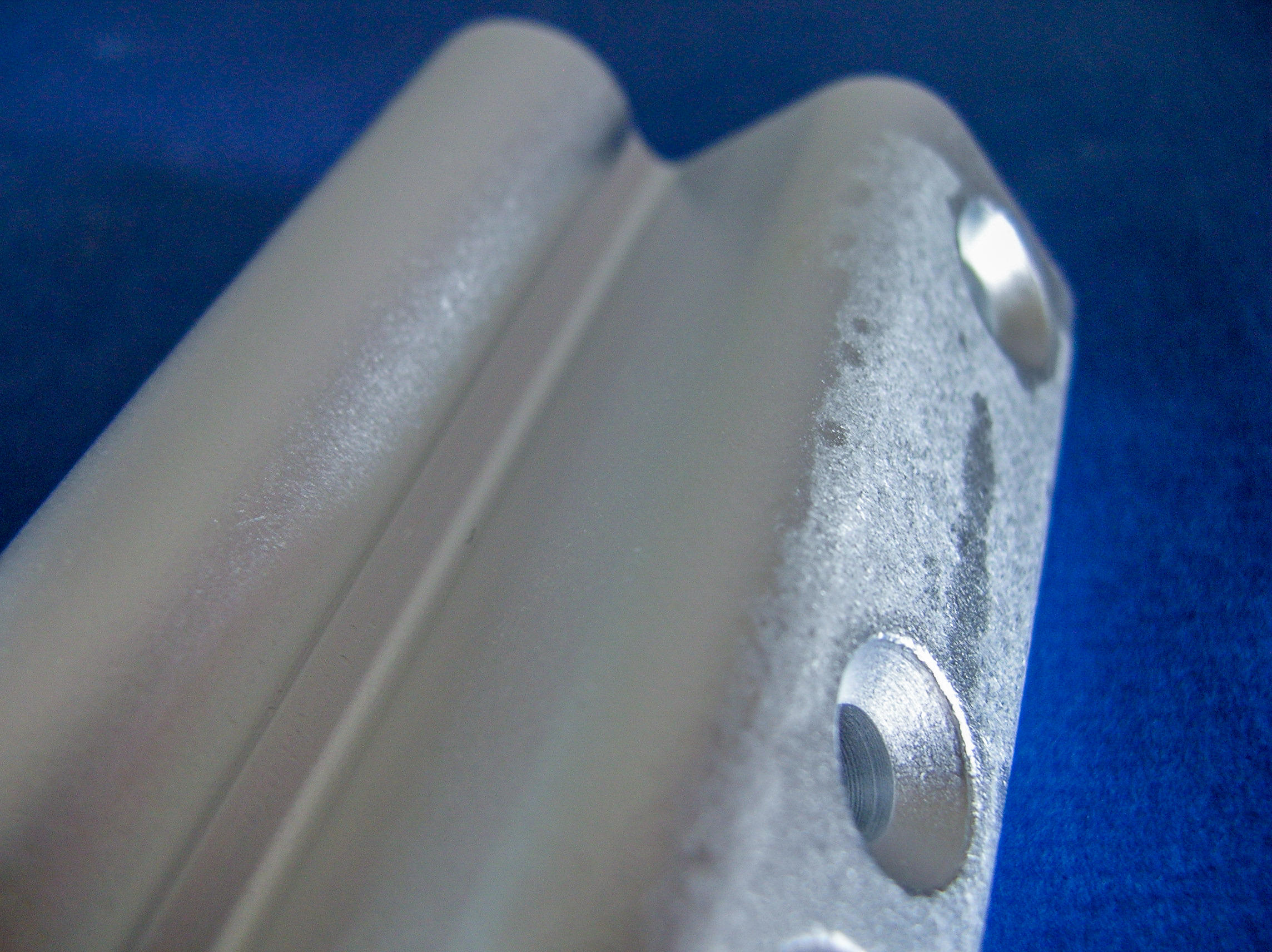

Due to residues remaining on the surface after cleaning, there is a different removal of material on the aluminium surface during matt pickling. While the correctly cleaned material is etched immediately, material is only removed from the areas with residues once these have been removed. This results in relief formation, which then leads to the error pattern. The defect is also clearly visible in the case of foil residues that have remained unnoticed on the metal surface:

How can the error pattern be avoided?

Avoiding the defect is simple. The raw material should be inspected for corresponding residues before chemical pretreatment. Residues are often also found on edges and recesses. Organic adhesive residues can usually be easily removed with organic solvents.

Anodised and sealed final product - not saleable

Relief formation on pickled aluminium surface due to remaining foil residues