For the decorative matting of aluminium surfaces in the anodizing process, alkaline pickling processes are predominantly used in Europe. These special etching bathes are applied in accordance with the DIN 17611 standard for “E6” surface treatment. Such etching bathes are also referred to “E6 etching bathes “. With correct bath management, decorative, fine matt aluminium surfaces are obtained with them.

These long-lasting pickles are very robust if you do the necessary bath maintenance. Especially with high aluminium contents, which are needed for a matt, decorative stain finish of the aluminium surfaces, correct bath management is necessary. This prevents the bath from becoming unstable. If one is negligent here, it can lead to the precipitation of aluminium hydroxide in the bath, which can lead to a total loss of the bath.

Characteristic for these alkaline pickles is their high content of dissolved aluminium, defined proportions of sodium hydroxide, complexing agents and corresponding precipitating agents. Various Alfisatin products, for example, are used for this pickling process. The precipitants remove foreign metals from the aluminium alloy and form insoluble or poorly soluble metal sulphides (usually very fine, black particles) with them. Depending on the proportion of precipitated foreign metals in the aluminium alloy, the E6 etching bath solution thus quickly turns into a deep black coloured process bath. The fine, black pigments do not interfere with the pickling process.

For particularly matt surfaces, high aluminium contents are required in this etching bath, which may well be more than 200 g/l. With such high aluminium contents, special attention must be paid to the stability of the etching bath.

How can I easily control if my E6 etching bath is stable?

Just one look at the etching bath usually reveals whether the bath is still stable. If it shows a deep black colour, you can assume that the bath is sufficiently stabilized. Of course, this optical impression should always be confirmed by regular bath analyses.

The E6 – etching bath is turning more and more grey – what has happened?

If the pickling bath shows a grey colour instead of black, you have to react immediately. In this case, a destabilization process has already occurred. In this process white, poorly soluble aluminium hydroxide has precipitated in the bath. If its proportion in the bath continues to increase, the bath becomes increasingly grey, i.e. the previously black colour changes via dark grey – medium grey – light grey until the bath finally appears completely white. In the light grey to white state, the bath is lost and must be renewed, which involves a considerable amount of work and time. Therefore, one should always try to avoid this state.

How to save a unstable grey bath?

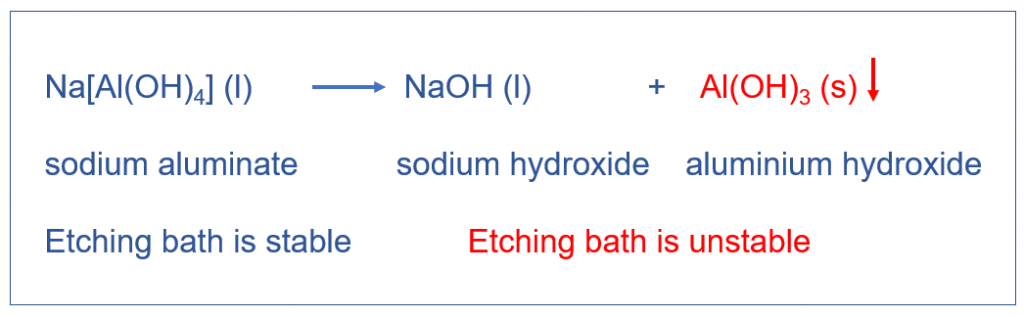

If the E6 pickling bath has turned slightly grey, a comprehensive bath analysis should be done immediately. You will recognize the instability by a decreasing aluminium content (part of the dissolved aluminium has already precipitated as poorly soluble aluminium hydroxide). At the same time, the sodium hydroxide content will increase, as sodium hydroxide is released during destabilization:

It would be a mistake not to add any more sodium hydroxide to the bath, as its content is obviously still within the specified target range. Low alkalinity promotes further destabilization of the pickling bath. A large amount of pickling additive (Alfisatin) should now be added to the grey bath for additional stabilization, e.g. twice the previous amount. It is also recommended to increase the alkalinity of the bath (addition of caustic soda lye or sodium hydroxide) in order to stabilize it additionally.

These stabilization measures can ensure that no further aluminium hydroxide precipitates and that the existing aluminium hydroxide is discharged again via the pretreated aluminium surfaces. In this way, the bath can usually be returned to a stable state (black colour). During this time, continuous analyses for bath monitoring are particularly important. If the black colour returns to the bath, the stabilization has been successful.

Is it possible to save a light grey or milky white E6 pickling bath?

If the bath has reached this state, it is no longer possible to save it. You can only wait a certain time until the white sludge has settled at the bottom of the pickling bath. The supernatant clear phase can then be transferred to an empty bath container and, depending on its condition, can be used for a new bath preparation. However, the precipitated white aluminium hydroxide sludge should be removed from the pickling bath immediately and disposed of. If you wait too long, it will become stony and difficult to remove from the bath.

Summary

Destabilization should always be avoided and carries the risk of losing the entire pickling bath. Saving the bath is only possible up to a certain level. Regular bath checks and operation outside critical limit ranges (sodium hydroxide content below the minimum concentration; too low pickling additive (Alfisatin) content) enable safe and stable management of the alkaline E6 pickling bath.